Wear Parts

ADDITIONAL WEAR PROTECTION

- Provide a layer of hard wearing material to protect the original structure of your attachment.

- Or, to hold dirt in the crevasses to allow a dirt on dirt wearing system as opposed to steel on dirt. Welding material in a place to stop the general flow of material past the original structure of the attachment works best to prevent wear.

Each of these types of systems have their own advantages depending on the type of material in which the attachment is working.

A wear package, also known as an armour package refers to a set of add-on protective measures that can be applied to your earthmoving buckets and attachments.

These measures can include reinforced components or specialised coatings that help protect the buckets from damage due to abrasion, impact, or other hazards commonly encountered on construction sites or in tough working environments.

Wear parts are replaceable components that are designed to wear out over time and be easily replaced therefore, saving you money by not having to replace your entire bucket.

At ShawX, we can design a custom wear package to suit any attachment, including your existing buckets.

The components included in your wear package will depend on your specific bucket and the demands of your application. We work with our engineers to customise a package to best suit you.

By adding a wear package to your equipment you can help reduce downtime, increase productivity, and extend the lifespan of your equipment, saving you money in the long run, which is always our goal.

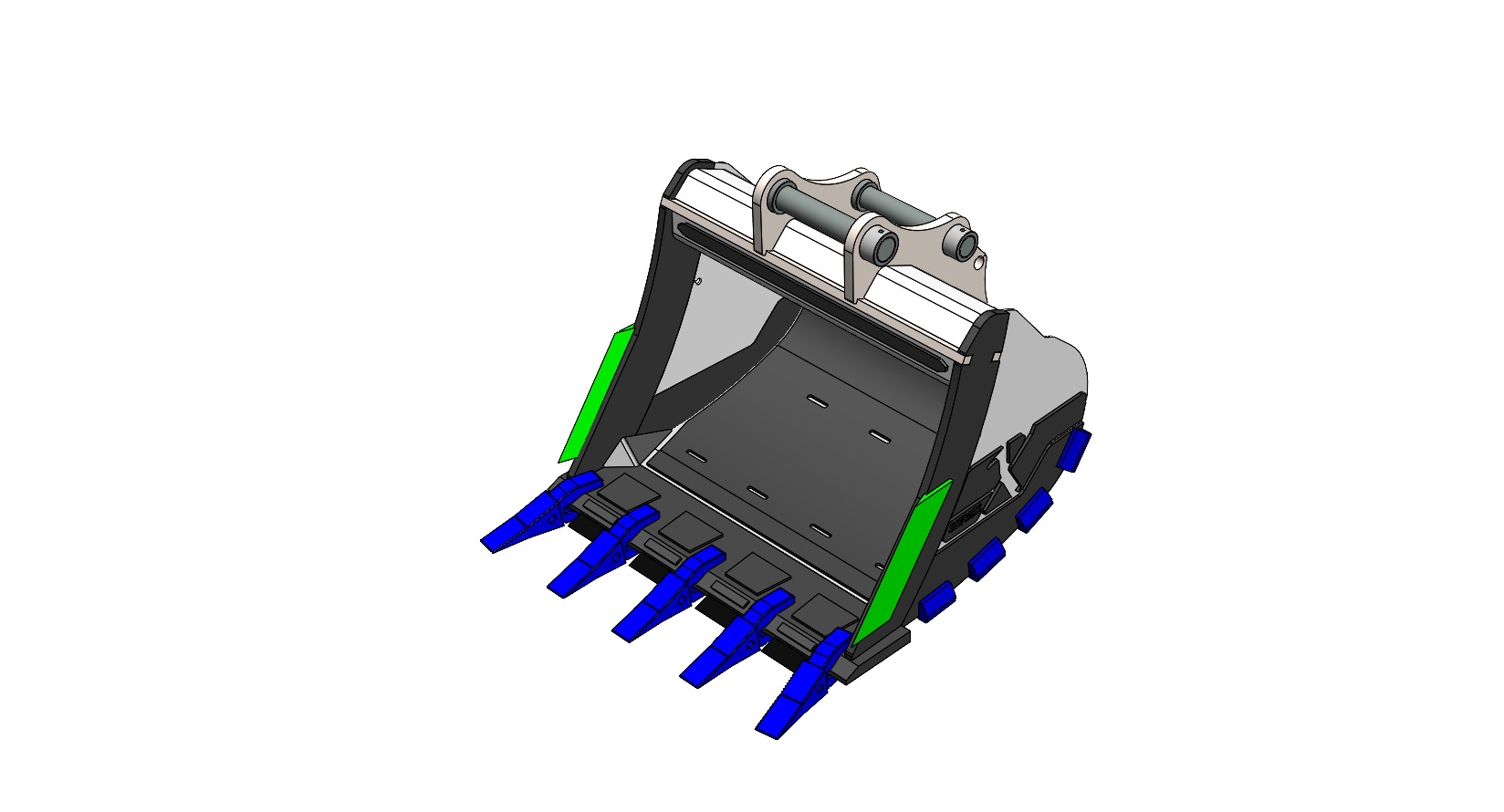

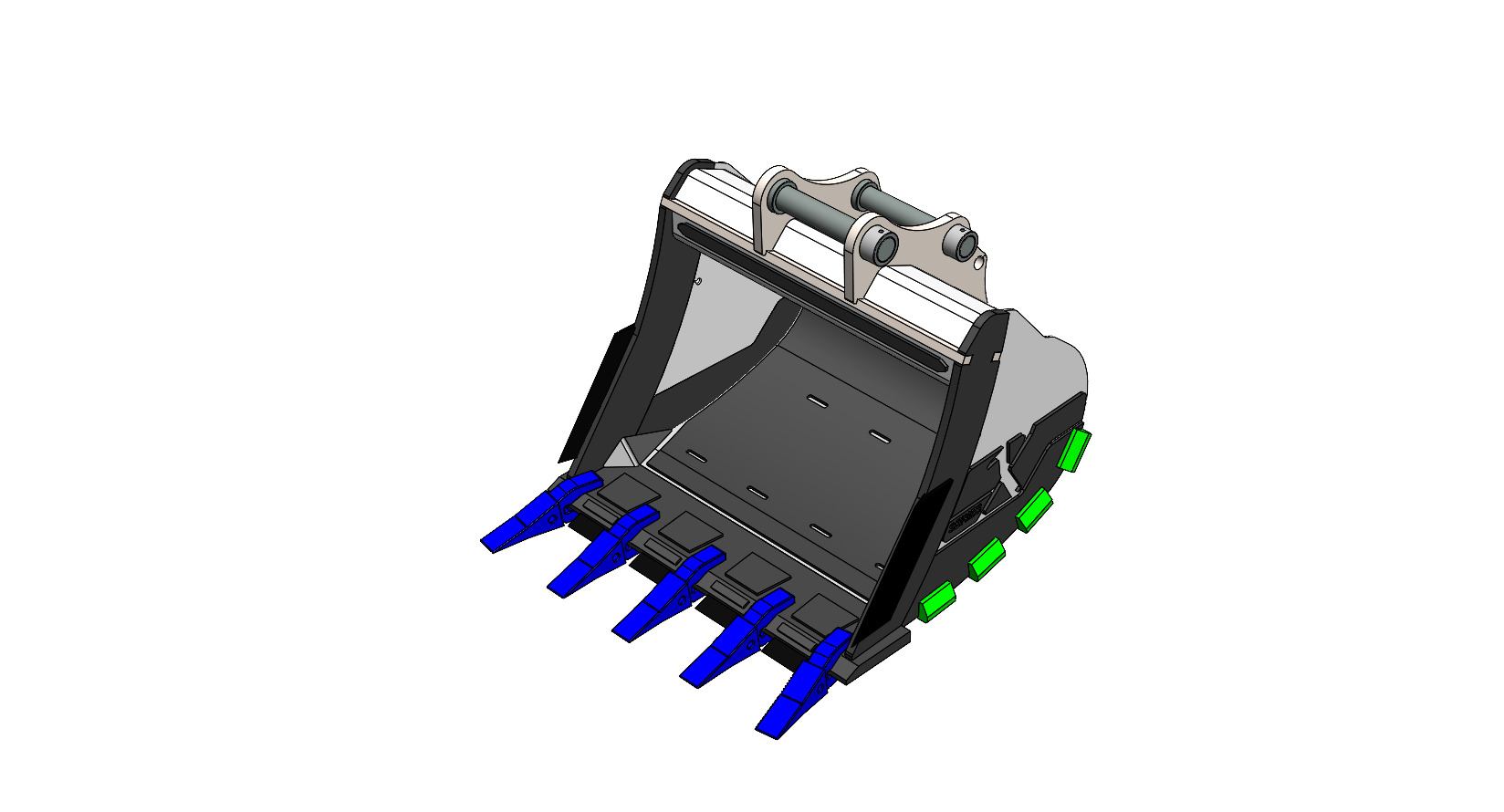

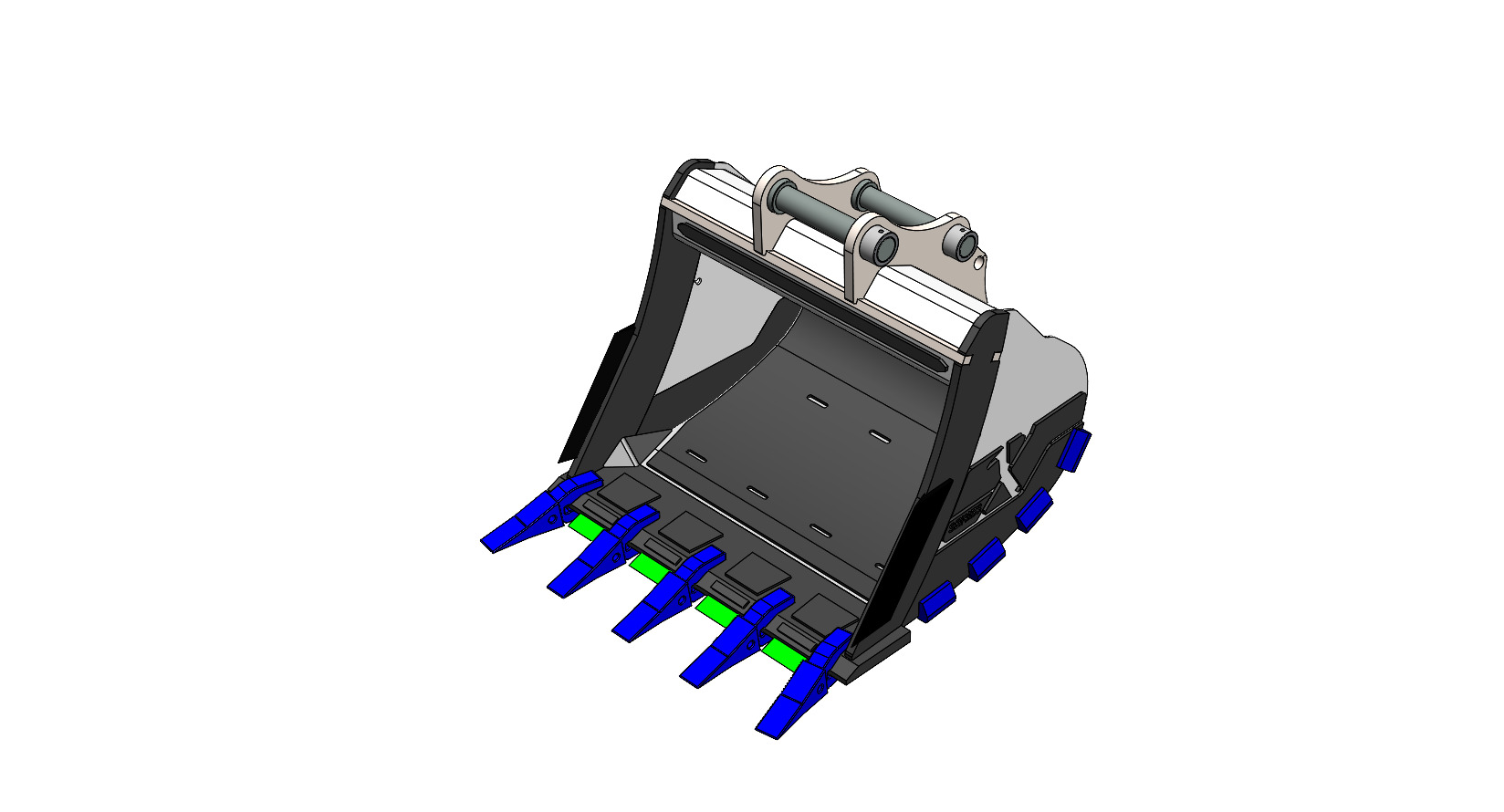

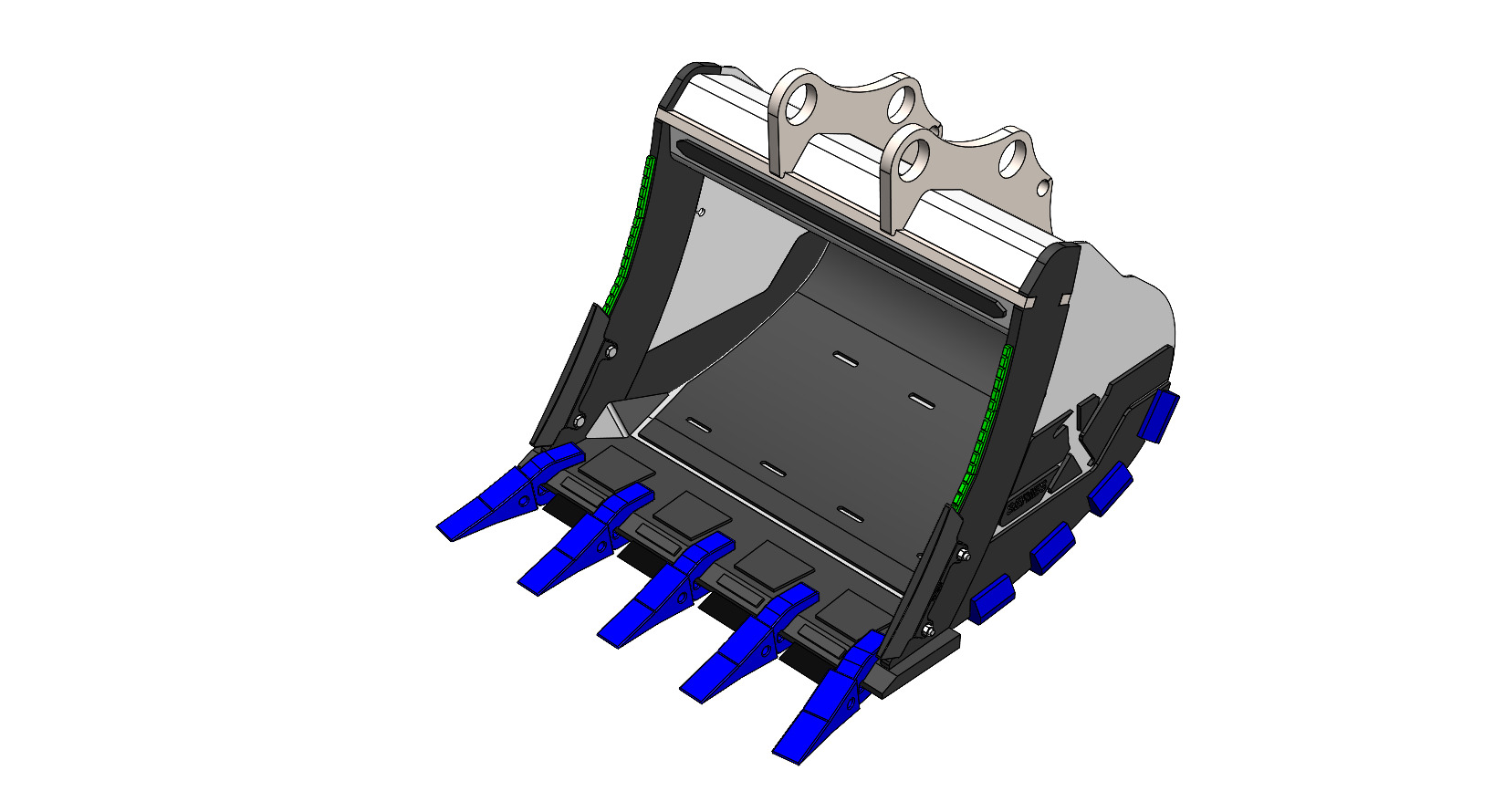

Side Cutters

Side cutters, also known as wing shrouds, are metal plates that are attached to the sides of your bucket to increase its durability and cutting power. They are designed to protect the bucket’s sides and legs from wear and tear caused by abrasion and impact. Side cutters also help to increase the buckets capacity and cutting efficiency by providing additional cutting edges that can be used to slice through tough materials like rock, concrete, asphalt and hard ground.

Side cutters can be bolt on or weld on. Although bolt on is most common as this allows for easy replacement once worn or damaged.

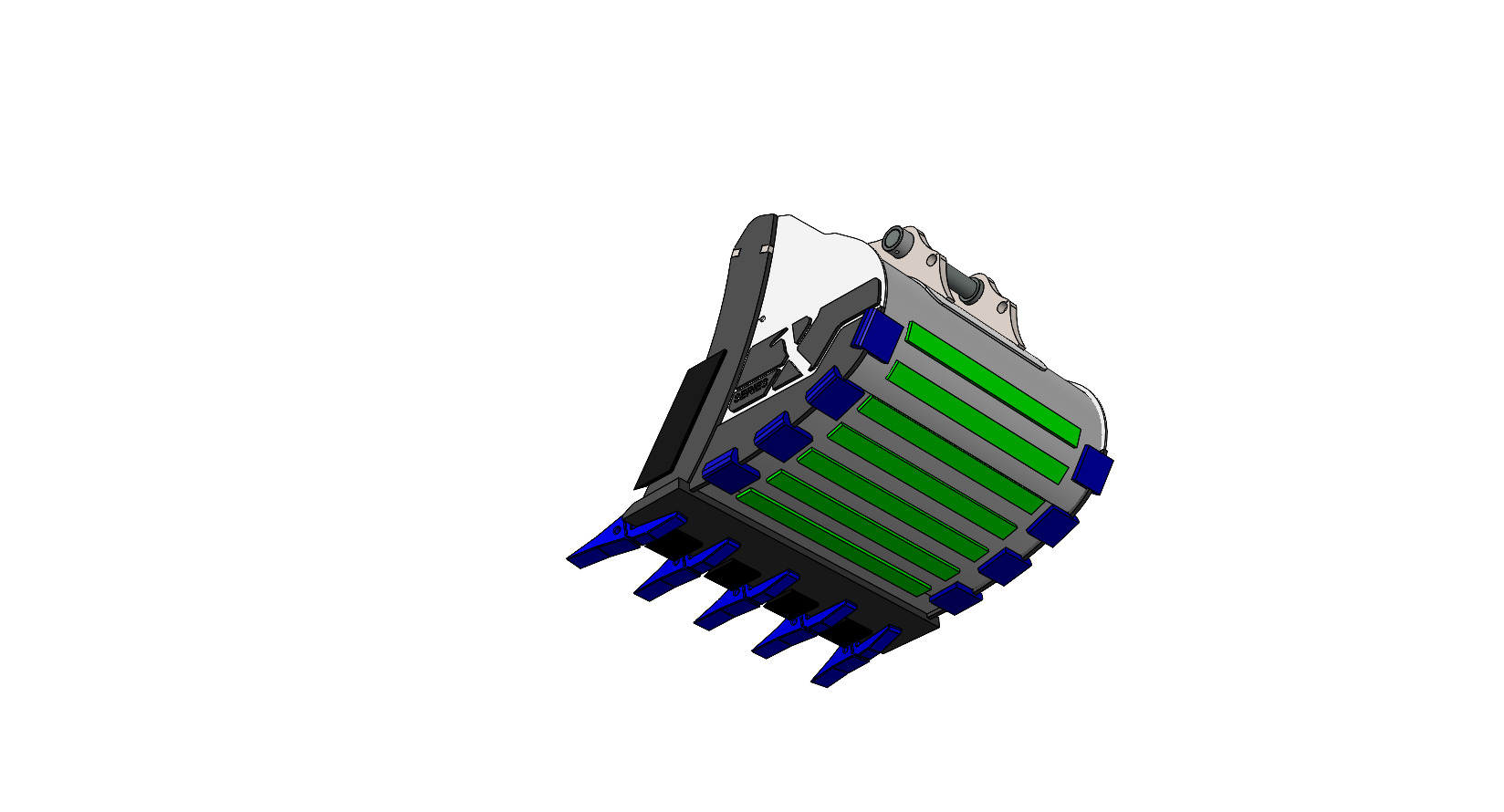

Rear Wear Strips

Rear wear strips are metal strips or plates attached to the underside of the bucket to protect it from wear and tear. These strips are made of a high-strength steel and are designed to absorb the impact of constant digging.

Rear wear strips help to extend the life of your bucket as they are typically welded on and are designed to hold dirt to provide a wear barrier . They are then replaced once worn or damaged, saving your bucket skin wearing.

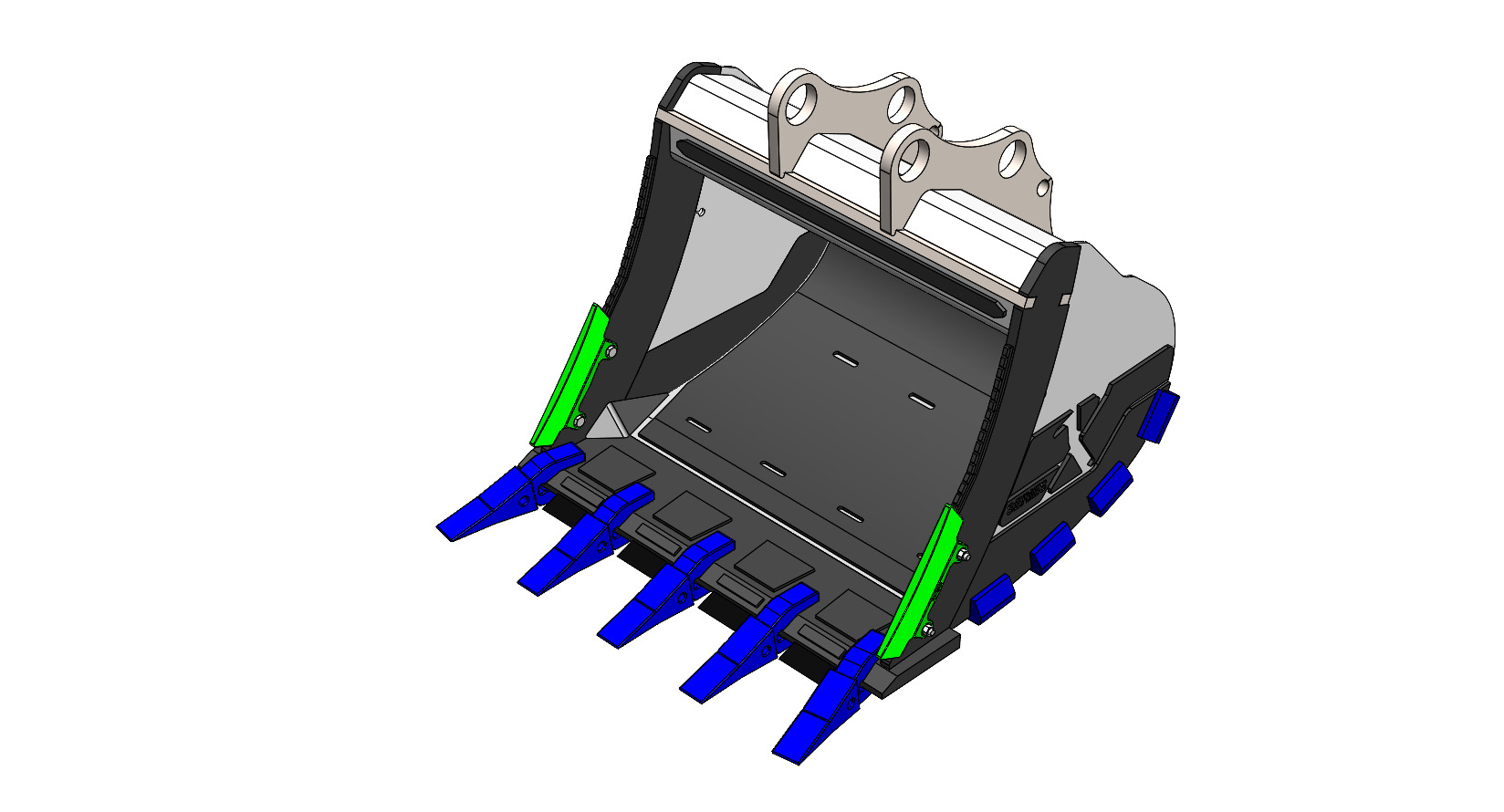

Side Wear plates

Similar to Rear wear strips, side wear plates are metal strips or plates that are attached to the sides of your bucket to protect it from wear and tear. They are typically made from a high-strength steel and are designed to absorb the impact of constant digging and materials causing abrasion.

Side wear strips are generally welded onto the bucket and are replaceable once worn or damaged. They can be an important component of your bucket if excavating in hard or abrasive materials, such as rock, gravel, and concrete.

On a ShawX bucket our lower side wear plate is in fact cut into the bucket to ensure protection on both the inside and outside of your bucket for no extra cost.

Talk to the team at ShawX to see what else we do as a standard fit to provide longevity on your bucket.

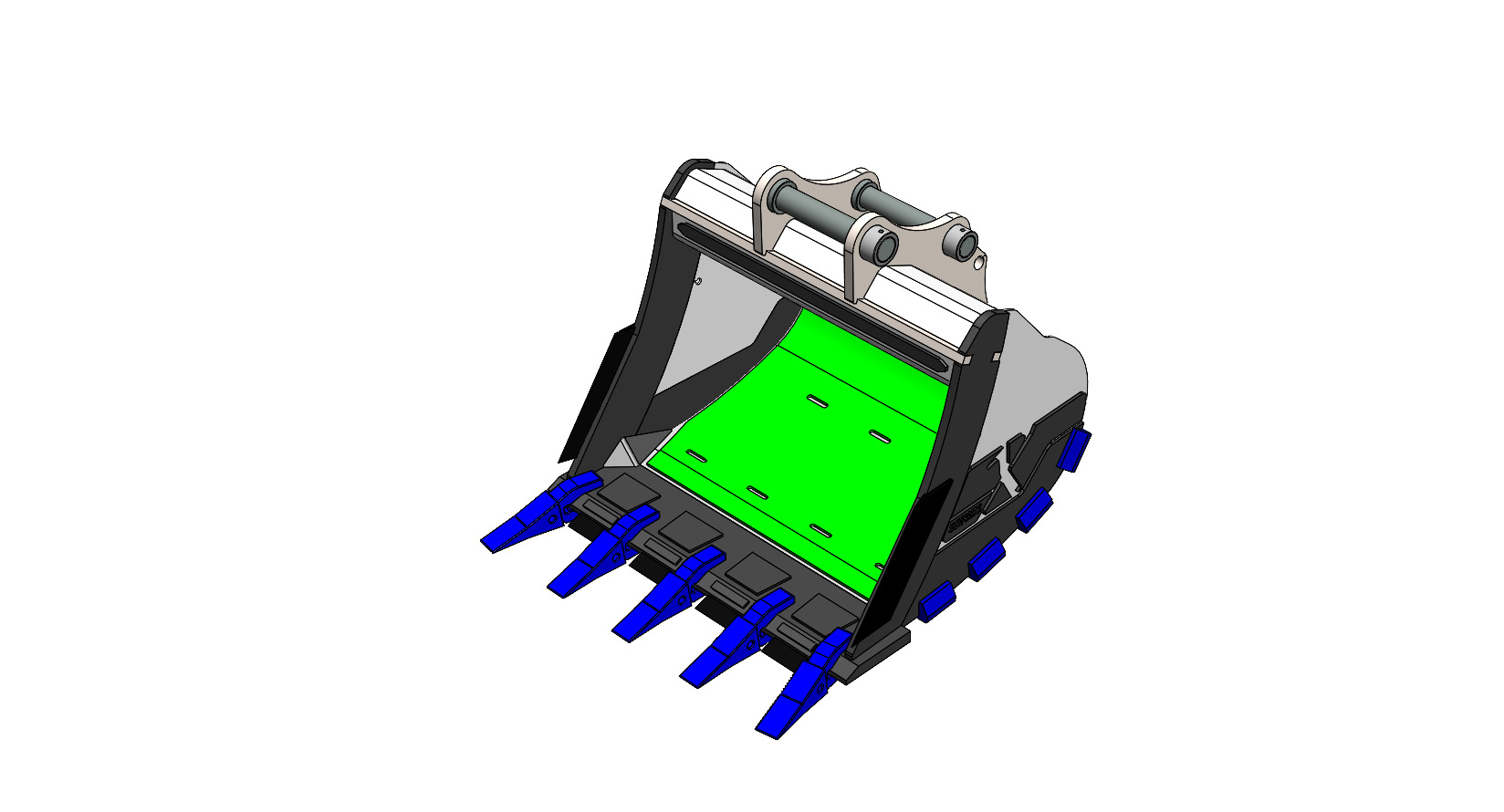

Internal wear liners

Internal wear liners are protective plates that are installed inside the bucket, either on the cheeks of your bucket or directly on top of your bucket skin to protect your actual bucket from wear and damage. These liners are then replaced to extend the life of your bucket.

Heel Blocks

Heel blocks are metal blocks or plates that are attached to the bottom or rear of your bucket. They are designed to provide additional wear protection by preventing damage to the bucket’s heel or rear edge by absorbing the impact of materials being dumped or dragged by the bucket. Heel blocks are either bolted on or welded on and are replaceable when they become worn or damaged.

Heel blocks help extend the life of your bucket and reduce repair costs by protecting the bucket’s structural components.

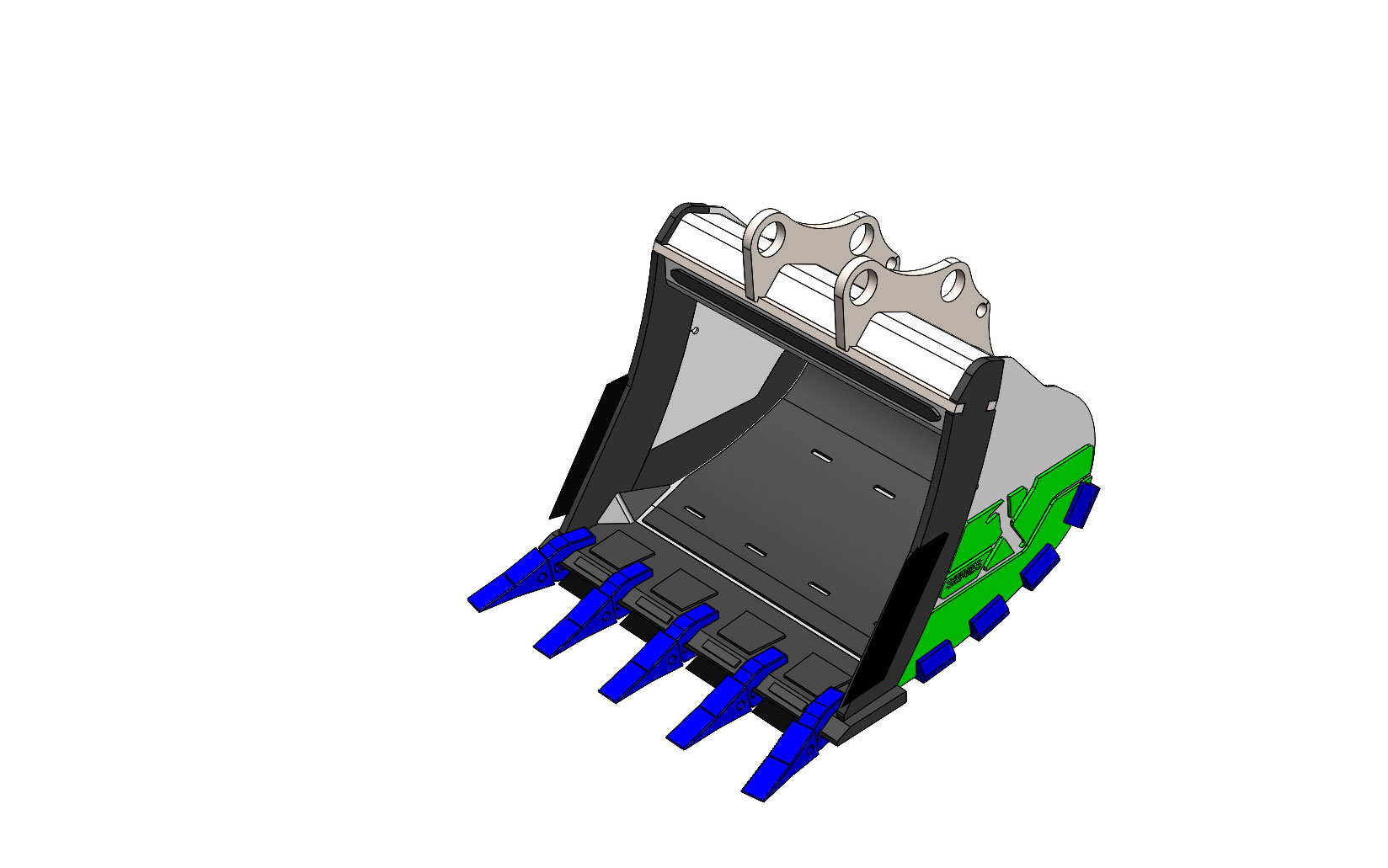

Leg protectors

Leg protectors, similar to side cutters, are a hardened steel that are bolted on to cover most of the length of the sidebars, designed for countering abrasion and impact.

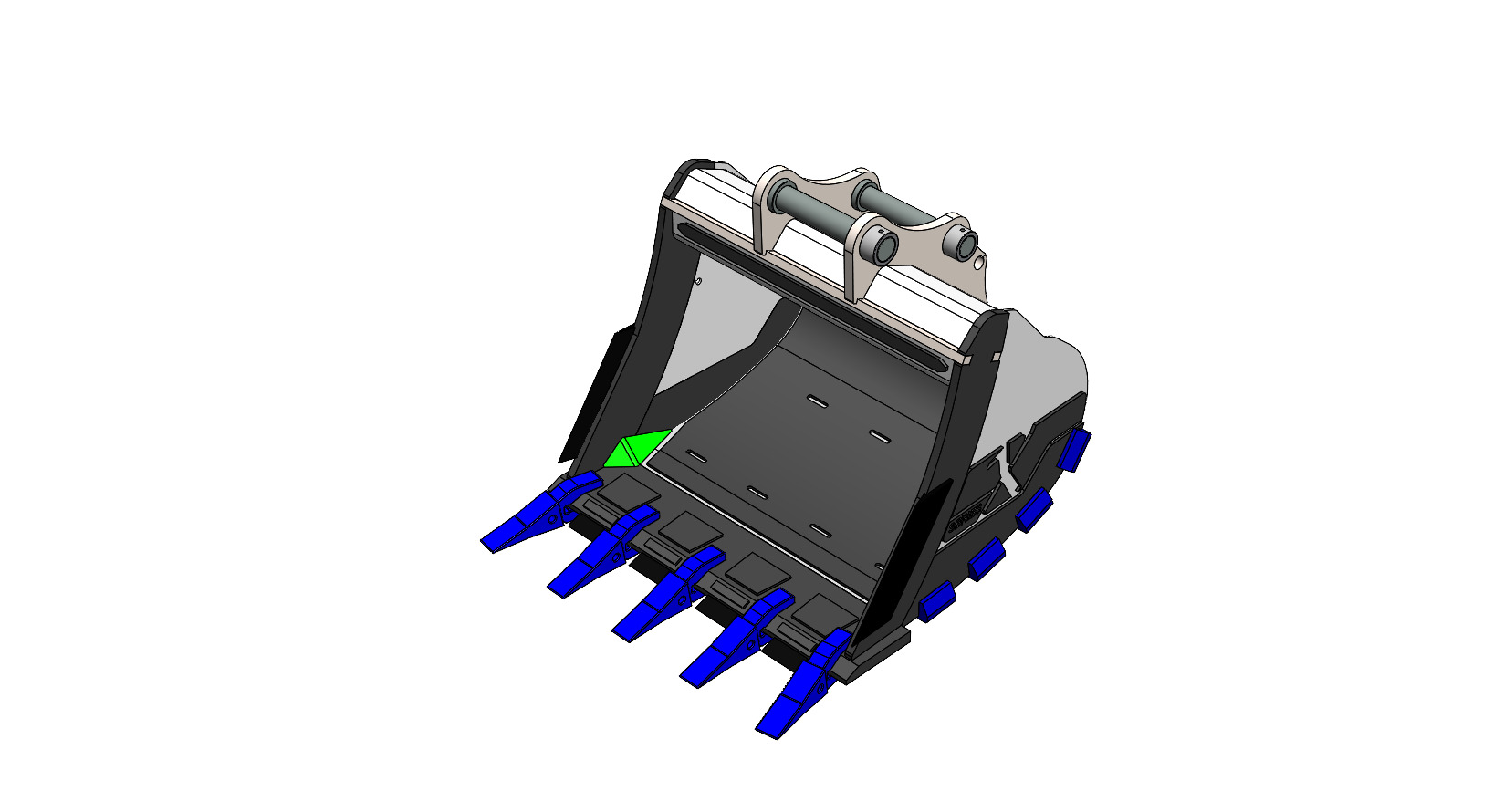

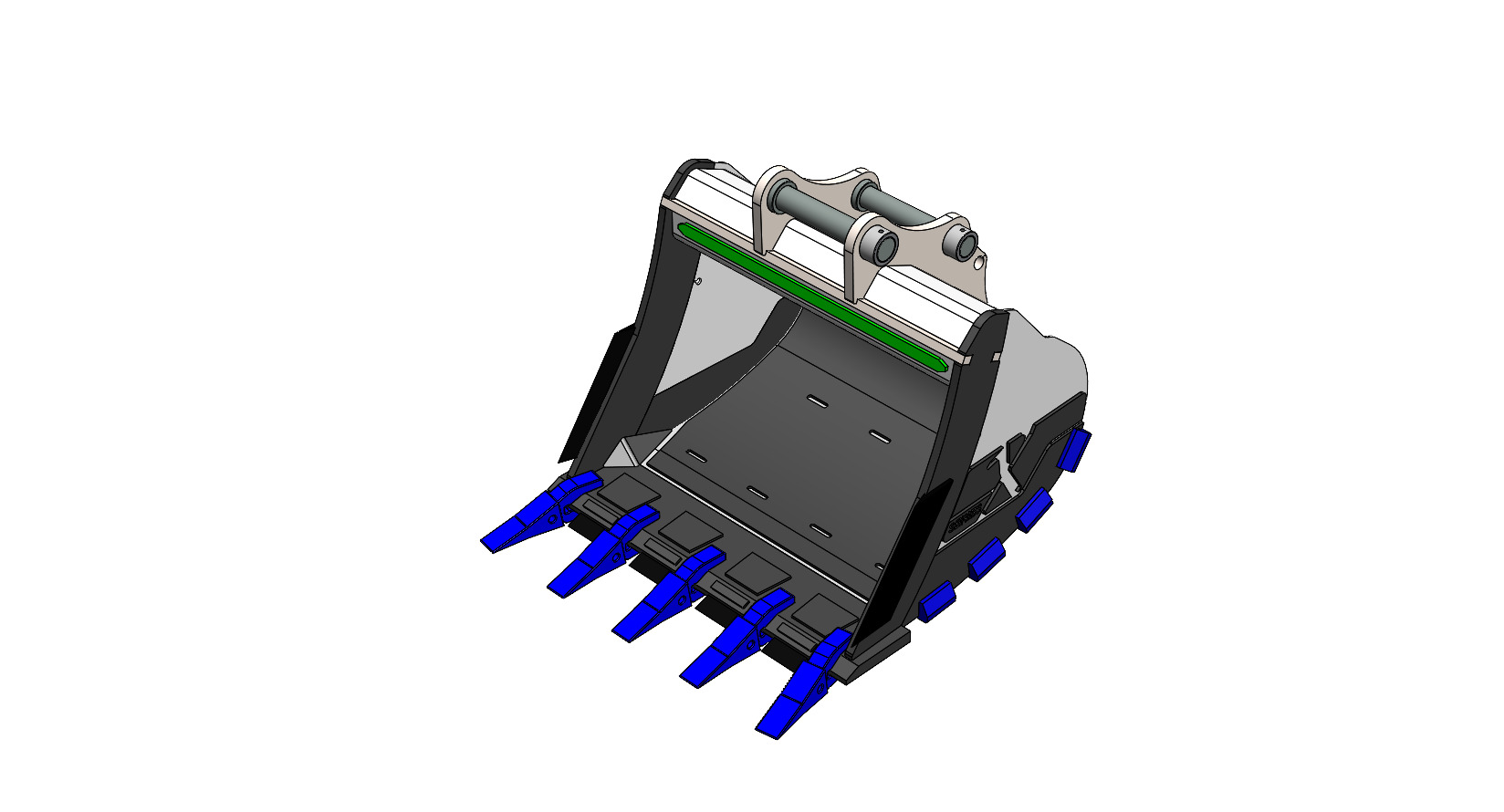

Top edge protection

Top edge protection is either plates or a strip that is welded to the top side of your base edge, designed to protect the leading edge of your bucket, which is the most exposed to abrasive materials and impact.

Corner Gussets

Corner gussets are reinforcement plates that are welded to the corners of an excavator bucket to strengthen and reinforce the buckets structure. Corner gussets are made of high-strength steel and are designed to absorb and distribute the stresses and forces that occur during digging. Corner gussets are an important component as they help to prevent deformation and cracking of the buckets corners, which are areas subjected to significant stresses and wear. By adding extra strength and reinforcement to the buckets corners, the corner gussets help to improve the durability and performance as well as, extending the life of the bucket and reducing repair costs and time.

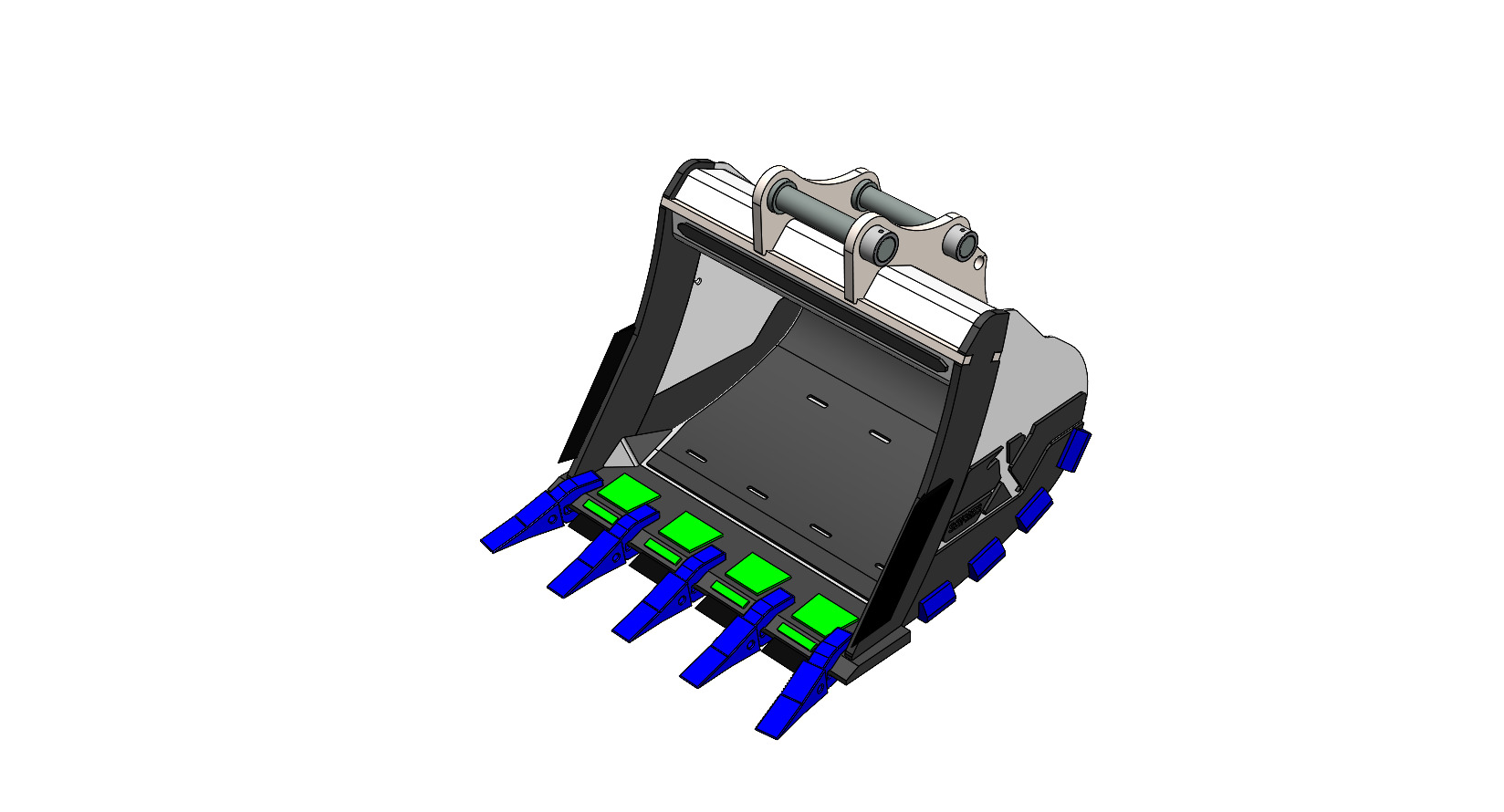

Lower Edge Gum protection

Lower gum protection can be a variety of either welded or bolted wear parts fitted between the adaptors on heavy duty rock buckets to prevent premature failure and excessive wear of the base edge in hard wearing applications such as rock and concrete.

Boxing Rock guard

Boxing Rock Guard is for those that work in heavy rock. It provides extra protection for the top of your bucket when large rocks are constantly hitting against the boxing, preventing damage and premature wear.

Chock Blocks

Chock blocks, also known as chocky bars, are used for a variety of applications on buckets. They can be welded anywhere that is wearing. They can also be used alongside other wear parts to give extra advantage and protection. The notched backing makes them easy to bend into place and cut to size, providing wear protection on both flat and contoured surfaces.

Weld on or Bolt on wear protection?

Options for your wear parts include mostly pinned/ bolted, or fully welded packages.

Things to think about when deciding what option is right for you:

If your working with crushers, screens or any sort of fixed plant, weld on is generally the preferred method because inevitably a bolt or pin system will fail leaving you with the possibility of your wear part going through your crusher. This is why we generally weld most wear parts.

However, when your welded armour package is worn out and needs to be replaced, it will need to be cut and removed to replace. Meaning the downtime is longer.

Both options have their benefits, it is just choosing the option that is right for you, your application and your work environment.

Talk to our team to ensure you make the right choice.